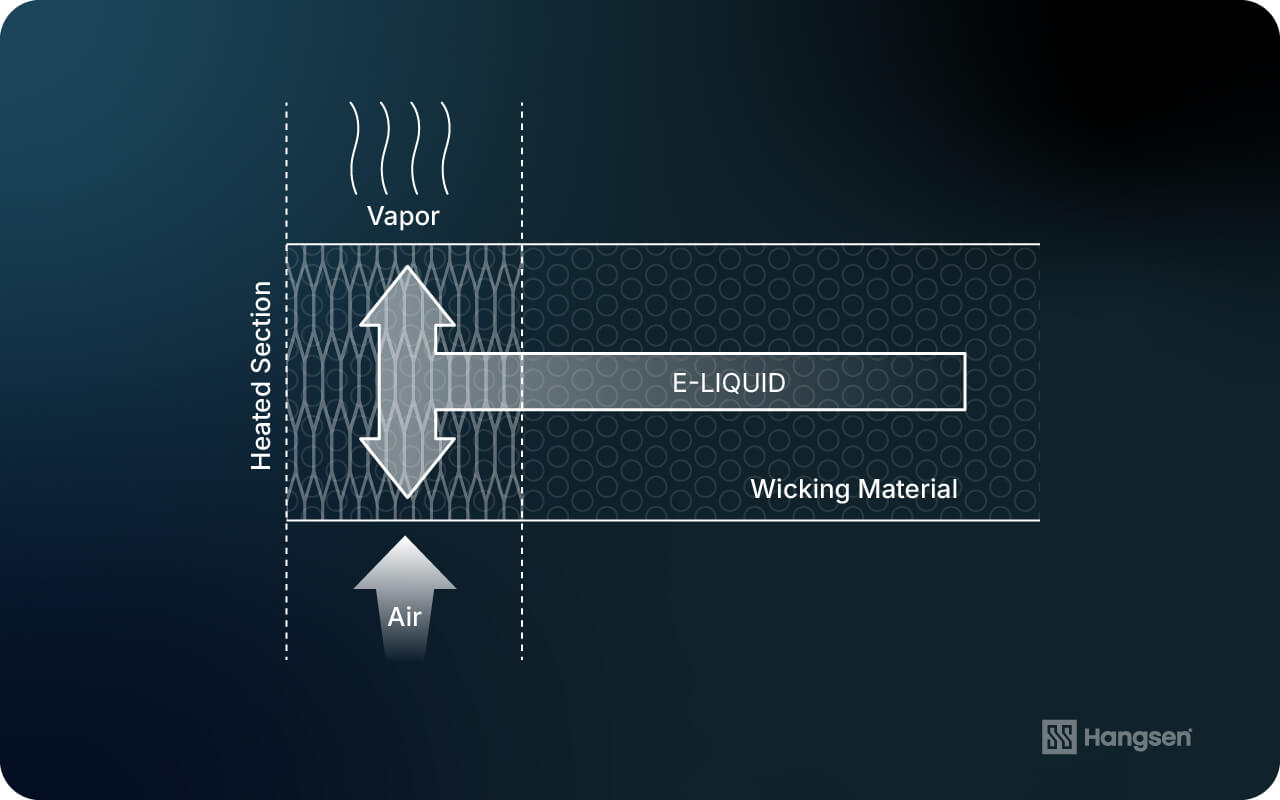

Wicking rate refers to the speed at which e-liquid is transported from the reservoir to the coil through the porous wicking material in a vape. This process involves the movement of e-liquid from a reservoir (typically a tank) through a porous material (wick) to the heating element (coil).

Various factors, including the properties of the wick, the e-liquid's viscosity, and the vaping device's design influence this process's efficiency. The wicking rate directly affects the continuity and stability of e-liquid supply during use. It is a dynamic factor that changes with conditions, such as the saturation of the wick during puffing.

In theory, the wicking rate can be calculated using Darcy's Law, combined with the liquid's viscosity, the wicking material's permeability, and capillary pressure. However, since the saturation of the wicking material fluctuates with use, which further impacts permeability and capillary pressure, it cannot be accurately calculated using a simple static model. Through practical testing, it can be observed that permeability is non-linearly related to saturation, while capillary pressure is linearly related to saturation.

By analyzing these dynamic factors in simulations, the wicking performance of vapes can be predicted more accurately, helping to optimize product design, reduce potential design issues, and save development time and costs.

Factors Affecting Wicking Rate

1. Characteristics and Structure of Wicking Material

Pore Structure of the Material

The porosity and pore size distribution of the material directly affect its wicking performance. Higher porosity enables the material to absorb and transport more e-liquid, while smaller pore sizes typically generate higher capillary pressure, which increases liquid transport efficiency. Therefore, when selecting materials, it is essential to balance porosity and pore size to ensure stable liquid transport.

Wettability of the Material

Wettability directly impacts the spread and transport of e-liquid across the material's surface. Good wettability can enhance capillary pressure and permeability, thus improving wicking efficiency. When choosing wicking materials, priority should be given to those that exhibit good wettability with e-liquid to ensure smooth liquid transport to the coil and improve overall vaporization performance.

Introduction to Wicking Materials

Cotton Wicks

Organic cotton, due to its natural fibers and excellent absorption capabilities, is commonly found in devices where users can manually refill e-liquid, such as traditional tank systems and open pod systems. However, it also has some drawbacks, such as a tendency to dry burn and accumulate carbon buildup over time.

Ceramic Wicks

Ceramic materials are often found in closed pod systems. They provide durability and heat resistance, making them a reliable choice for consistent performance. The porous nature of ceramic allows for controlled wicking, which is particularly beneficial in devices where maintaining a stable supply of e-liquid is crucial.

However, the slower wicking speed of ceramic materials can sometimes result in lower flavor intensity compared to other materials, such as cotton or synthetic fibers. Despite these limitations, ceramic materials are valued for their longevity, uniform heating properties, and ability to prevent dry hits and leaking.

Synthetic Fiber Wicks

Synthetic fibers, such as PET, PVA, PP fibers, and PE fibers, combine the advantages of both ceramic and cotton materials, offering a balance between durability, heat resistance, and efficient wicking performance. These fibers provide consistency in liquid transport like ceramic materials, while also maintaining good absorption properties similar to cotton.

With their engineered three-dimensional network structure (porosity ≥ 95%), they exhibit highly stable and uniform physical properties. These features make synthetic fibers highly effective in preventing dry hits and reducing carbon buildup, contributing to their widespread use in disposable vape devices.

2. Device Structural Design

The distance the liquid travels, device orientation, and coil design—including the wicking path length, material diameter, and contact area—are all crucial factors affecting wicking efficiency. In the current market, common large-capacity disposable vape designs often adopt an integrated wicking and storage structure, where a single piece of wicking cotton wraps around the mesh coil, rather than using a separate tank. This structure simplifies the wicking path, significantly boosting wicking efficiency.

Moreover, the contact area between the wicking material and the coil is key to optimizing the wicking rate. In some disposable devices, designs such as dual mesh coils are adopted to further increase the contact area, allowing the liquid to make more complete contact with the coil. This ensures even heating and stable vaporization, effectively preventing issues like localized overheating or insufficient heating, significantly enhancing the device's overall performance and user experience. From a certain perspective, this is also a way to improve the overall wicking efficiency of the coil.

3. Physical Properties of E-Liquid

The viscosity of the E-Liquid: The thickness or viscosity of the e-liquid plays a crucial role. Higher viscosity (typically in VG-rich liquids) slows down the wicking process, while lower viscosity (PG-rich liquids) facilitates quicker wicking.

E-liquids with higher PG content tend to have lower viscosity, enhancing wicking speed, while those with higher VG content are more viscous and may cause wicking issues, particularly in materials with lower wicking performance, leading to dry hits.

Therefore, during development, it is essential to select suitable wicking materials based on the target vapor production to avoid performance issues.

4. Operating Conditions

The power of the device and the frequency of puffs directly affect the wicking rate. Frequent puffs and higher power accelerate e-liquid consumption, reducing the saturation of the wicking material, which in turn lowers wicking efficiency. Therefore, in practical testing, it is crucial to consider the impact of different puff frequencies on wicking rate and device performance.

5. Environmental Factors

External factors such as temperature, humidity, and pressure also affect the wicking rate. Higher temperatures typically lower the viscosity of the liquid, improving wicking speed, while high humidity or low pressure may hinder liquid transport, affecting wicking efficiency. During product design, it is essential to conduct comprehensive testing based on the environmental characteristics of different markets to ensure optimal performance under various conditions.

The Role of Wicking Rate in E-liquid Development

The wicking rate plays a crucial role in the design of e-cigarettes and the development of e-liquids, directly impacting device performance and user experience. Here are a few key application scenarios:

1. Avoiding Dry Hits and Bitterness

When high-power devices are paired with wicks that have a low wicking rate and high-viscosity e-liquids, insufficient e-liquid supply may lead to dry hits. Dry hits not only result in a bitter taste but may also cause the e-liquid components to degrade, releasing harmful substances like carbonyls, aldehydes, and benzene. When matching the wick to the e-liquid, it is crucial to balance the relationship between e-liquid viscosity, wicking rate, and device power to ensure stability and safety under all usage conditions.

2. Maintaining Rich Flavor

If the wicking rate is too high, e-liquid may flow too quickly to the coil, carrying away too much heat, which could lower the coil’s temperature, affecting the release of flavor components that need higher temperatures for full vaporization, thus weakening the flavor. Adjusting the e-liquid's viscosity or optimizing device power can help maintain the coil at its ideal operating temperature, ensuring full release of flavor components.

During the e-liquid development process for closed devices, device power is typically adjusted, or e-liquid viscosity is improved to match a high wicking rate, helping the coil maintain its optimal operating temperature.

3. Reducing Leakage, Spitting, and Condensation

When the wicking rate is too high, e-liquid flows rapidly into the atomizer head, potentially exceeding the coil's evaporation capacity. As a result, some of the e-liquid may not fully evaporate in time, accumulating around the atomizer head or near the mouthpiece, which exacerbates issues such as leakage, spitting, and condensation. By optimizing the wicking rate parameters of the device, these issues can be mitigated to some extent.

4. Extending Product Lifespan

An improper wicking rate may lead to rapid e-liquid consumption or dry hits, thereby affecting the device's lifespan. In practical development, common methods include adjusting e-liquid viscosity and wicking materials to improve the lifespan of e-cigarettes and enhance user satisfaction.

Conclusion

The wicking rate is a critical factor in e-cigarette R&D, as it directly influences the efficient delivery of e-liquid to the coil, affecting both vapor production and overall performance. During the e-liquid flavor development phase, close collaboration between hardware and e-liquid teams is essential. However, by this stage, hardware designs are often finalized, making adjustments difficult.

Therefore, optimizing the e-liquid formula usually offers a more flexible and quicker solution to achieve the desired performance. Among these adjustments, ensuring that the e-liquid formulation is properly matched to the device's wicking rate is a critical task.

If hardware establishes the foundation for the product experience, the e-liquid determines how exceptional it can be. The ideal development process involves considering the relationship between device parameters, e-liquid properties, and product requirements from the start, ensuring that hardware and e-liquid are relatively well-aligned. This approach reduces the likelihood of needing significant hardware adjustments later, allowing for more effective e-liquid optimization during the flavor development phase, where perfect alignment is achieved.

At Hangsen, our product team combines deep expertise in e-liquid development with extensive experience in e-cigarette device R&D. This dual capability enables us to effectively identify and address product challenges from both hardware and e-liquid perspectives. During the early stages of R&D, we offer targeted optimizations for each client prototype, ensuring our solutions are precisely tailored to the unique specifications of every device. Through this approach, we provide cost-effective e-liquid solutions that enhance overall performance.

Feel free to Contact us at service@hangsen.com or leave a message on our Contact page.

Learn More

European E-Liquid OEM Solutions

E-Liquid Manufacturing Process: How to make the best vape juice?

HANGSEN INTERNATIONAL GROUP

Hangsen is a world-leading e-liquid manufacturer, offering custom flavor solutions for vape devices and premium white-label e-liquid services. Our e-liquids are renowned for their high consistency, stability, safety, and regulatory compliance. With business operations spanning over 80 countries and regions worldwide, Hangsen continues to set industry standards.