"How to make vape juice" is a topic often discussed among vapers. As we all know, Hangsen is a professional e-liquid manufacturer. So, let's switch gears today and delve into e-liquid production from an industrial standpoint, rather than providing beginners with a basic DIY juice-making tutorial.

E-liquid, also known as e-juice or vape juice, is a broad category encompassing various finished products commonly found on the market. This includes bottled freebase nicotine e-liquid, nicotine salt e-liquid, HVG e-liquid, shortfill, longfill, PG&VG base liquid, and flavor concentrates. Additionally, it includes bulk e-liquid customized for disposable vapes, closed pod systems, and other pre-filled devices.

In this article, we'll focus solely on the standard generic e-liquid manufacturing process, without delving into the distinctions between different types of e-liquids.

E-liquid Ingredients

Start by sourcing high-quality ingredients from reputable suppliers.

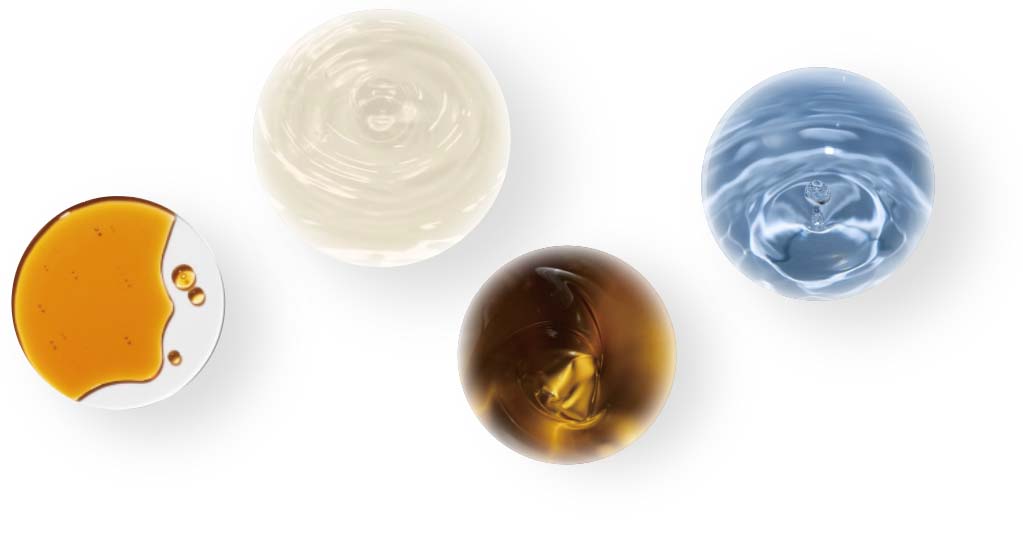

The main ingredients typically include:

Vegetable Glycerin (VG)

Vegetable Glycerin, also known as VG, as the name suggests, is an ingredient of glycerin extracted from plants. It is a simple polyol compound, a colorless, odorless, sweet-tasting, viscous liquid. Due to its stable and non-toxic characteristics, it is widely used in the food industry.

The Function of VG in E-liquid

Vegetable glycerin (VG) in vaping fosters dense vapor, is ideal for cloud chasers and provides a smoother inhale than propylene glycol (PG), catering to those preferring a gentler throat hit. VG enhances e-liquid flavors, adds sweetness, and acts as a thickening agent, improving texture, especially in high VG content e-liquids. Its humectant properties reduce dryness in the mouth and throat during vaping.

The VG and PG ingredients used by Hangsen comply with the standards of the European Pharmacopoeia (EP) and the United States Pharmacopoeia (USP).

Propylene Glycol (PG)

In both pharmaceuticals and the vaping industry, propylene glycol (PG) plays versatile roles due to its unique properties. In pharmaceuticals, PG serves as a solvent, aiding in the dissolution of active ingredients and facilitating drug delivery in various forms such as oral, injectable, and topical medications.

The Function of PG in E-liquid

In the vaping industry, PG is a key component of e-liquids. Acting as a carrier for flavorings and nicotine, it contributes to the production of flavorful vapor clouds when heated in electronic cigarettes. PG also serves as a thinning agent, ensuring the e-liquid has an optimal viscosity for vaporization. Additionally, it provides a throat-hit sensation similar to traditional cigarette smoking, which many former smokers find desirable during their transition to vaping.

Hangsen purchases VG and PG from leading global suppliers, including Procter & Gamble and Dow, for use in the e-liquid manufacturing process.

It is worth mentioning that Mr. Yao, the founder and chairman of Hangsen, was one of the pioneers who first introduced PG and VG as base liquids in the e-cigarette industry. As early as 2006, he led an engineering team to jointly develop e-liquid containing PG and VG components.

Nicotines

Nicotine, with the chemical formula C10H14N2, is a naturally occurring alkaloid primarily found in plants of the nightshade family and tobacco plants. It is highly addictive due to its ability to bind to nicotinic acetylcholine receptors in the brain, leading to the release of neurotransmitters such as dopamine, which reinforces addictive behavior.

The Function of Nicotine in E-liquid

Nicotine is widely utilized in tobacco products, smoking cessation aids such as nicotine patches and gums, and e-liquid. In e-liquids, nicotine is commonly added, often in the form of nicotine salts, which are known for their smoother throat hit and faster nicotine absorption compared to freebase nicotine. Nicotine salts are formed by combining nicotine with an organic acid, lowering its pH and neutralizing the strong stimulation of nicotine on the body, resulting in a more comfortable vaping experience.

In the e-liquid industry, nicotine salts commonly used is nicotine benzoate. However, recent studies have indicated potential safety risks associated with it, leading to its prohibition in certain countries. Apart from the typical nicotine benzoate, Hangsen offers a variety of nicotine salt options for customers to choose from. Additionally, in pursuit of optimal flavor performance, we do not limit ourselves to using just one type of nicotine salt during the e-liquid flavoring process. Based on the characteristics of the flavorings, we utilize different forms of nicotine or nicotine compounds.

Hangsen offers a wide range of nicotine varieties for the development of different nicotine e-liquids. Traditional freebase nicotine or Hangsen's latest development of the H-nicotine salts family, as well as the more pure MOTiVO™ synthetic nicotine. Hangsen's technology in the application of nicotine salt has been very mature, and more compatible nicotine salt can be selected according to different application scenarios to achieve the best flavor performance.

Flavorings

E-liquid flavoring refers to the substances used to add flavor to e-liquids. These flavorings can come in a wide variety of types and can be natural or artificial. Some common types of e-liquid flavorings include fruit flavors (such as strawberry, mango, or watermelon), dessert flavors (such as vanilla custard or chocolate), menthol or mint flavors, beverage flavors (such as coffee or cola), tobacco flavors, and many others.

The science behind e-liquid flavoring involves understanding the characteristics of different flavor compounds and how they interact with other ingredients like propylene glycol (PG), vegetable glycerin (VG), and various types of nicotine in the e-liquid. Additionally, factors such as the material of the atomizer coil, device power, and heating curve affect the performance of flavor.

The majority of Hangsen flavorings come from globally recognized flavor manufacturers such as Givaudan, Firmenich, Mane, IFF, and others. We also work closely with local high-quality flavor suppliers to fulfill our localized flavor requirements. In addition to pre-made flavorings, we collaborate with flavor manufacturers to create customized flavorings specifically designed for high-temperature vaporization in e-liquids. Regardless of their origin, all our flavorings meet the food safety standards of the exporting countries.

E-liquid Additives

Additives are extra ingredients added to e-liquids to change their taste, texture, or overall vaping experience. Additives commonly used in the e-liquid industry include Sweeteners for added sweetness, Cooling Agents for a refreshing sensation, and Acidic Regulators to adjust the acidity level. They help enhance the flavor and experience of the e-liquid when vaped.

Incorrect use of additives can lead to many problems, such as carbon buildup, coil gunk, bitterness, and even the production of harmful substances that corrode pod materials, posing safety risks. This has resulted in significant losses for many unprofessional e-liquid factories and substantial compensation payments to clients.

Correctly using additives not only helps avoid the aforementioned risks but also allows for perfect compatibility with the flavoring components in e-liquids, optimizing and enhancing vaporization sensation and flavor performance. Hangsen has matured in the application technology of additives. Coupled with an intelligent formulation computer-aided development system, our flavorists can precisely tailor additives based on e-liquid ingredients and specific devices.

It's essential to follow regulatory guidelines and safety standards when formulating e-liquids. If the product needs to be exported to Europe, the flavor ingredients need to meet the relevant requirements of Regulation (EC) No 1334/2008 Of The European Parliament And Of The Council Of 16 December 2008 On Flavorings And Certain Food Ingredients With Flavoring Properties For Use In And On Foods And Amending Council Regulation (EEC) No 1601/91, Regulations (EC) No 2232/96 And (EC) No 110/2008and Directive 2000/13/EC.

Crafting the Perfect E-liquid Formula

Once the raw materials are all set, it's time to get creative. We'll craft a formulation tailored to the customer's desired VG/PG ratio, nicotine type and strength, and flavor profile.

For white-label e-liquid flavors, customers can skip the flavor development step and proceed directly to the production process. However, customized e-liquid flavors typically require the creation of a bespoke flavor formula tailored to the customer's special needs or device compatibility. This custom flavor development process usually spans over a week, involving numerous rounds of testing, often dozens or even hundreds, alongside gathering customer feedback to refine and finalize a premium flavor profile.

Therefore, we typically advise startup companies or teams, especially those encountering budget constraints, to Start their business by capitalizing on white-label e-liquid services.

Hangsen provides a variety of best-selling flavors catalog, you just choose according to market preferences, and the rest of everything to us, you will easily start your own e-liquid brand business.

Learn More

White Label E-Liquid Flavors Catalog

Hangsen European White Label E-Liquid Services

What is Wicking Rate: A Brief Guide to E-Liquid Development

Mixing E-liquid with Precision

Set up a clean and controlled mixing area with proper ventilation. Use High Precision Scales to accurately measure each ingredient according to the formulation. Mix the ingredients thoroughly in a sanitized mixing vessel, ensuring even distribution of flavorings and nicotine (if used). During this process, we utilize fully automated mixing equipment to ensure consistency, unlike some small-scale factories that rely on manual stirring methods.

Quality Control and Testing

Hangsen production processes are strictly compliant with ISO 9001:2015, HACCP (according to CAC/RCP 1-1969 Rev. 4 (2003)), and good manufacturing practice (GMP) standards. Conduct quality control checks throughout the manufacturing process to ensure that the e-liquid meets safety and quality standards.

During the process, we conduct testing on both the gaseous and liquid states of the e-liquid, encompassing over 60 tests, including assessment of nicotine concentration, pH levels, microbial contamination, heavy metals, carbonyl compounds, alcohol, nitrosamines, and flavor consistency. We implement comprehensive testing procedures to monitor consistency between batches, ensuring product safety.

Bottling and Packaging

After the e-liquid is mixed and tested, it proceeds to the bottling and packaging stage. We use clean and sterilized bottles made from food-grade materials, featuring HS anti-counterfeiting markers engraved on the bottom. Hangsen employs precision equipment to fill the bottles with e-liquid, under the monitoring of the MES system (Manufacturing Execution System), ensuring precise volumes. This filling process occurs within our class 100,000 clean workshop, where it is executed by experienced workers following strict SOP (standard operating procedure).

Hangsen bottles are sealed with child-resistant caps to comply with safety regulations. Each bottle undergoes meticulous labeling, providing essential product details like nicotine strength, ingredients, warnings, and batch numbers. After the bottles are filled, labeling, plastic sealing, and packaging are completed on our fully automated packaging assembly line.

Storage and Distribution

Store the finished e-liquid in a controlled environment away from heat, light, and moisture to preserve quality. Implement proper inventory management practices to track batches and expiration dates.

Our warehouse consistently maintains a temperature of 20-28 degrees Celsius and humidity levels of 30%-75% for storage. Furthermore, our warehouse staff conducts daily checks on the storage conditions. Finally, we package the e-liquid in boxes or cartons, preparing them for distribution to retailers or clients.

Regulatory Compliance

Ensure compliance with relevant regulations and standards, including product safety, labeling requirements, and packaging regulations. Stay informed about changes in regulations, such as TPD(TRPR) in Europe, and update manufacturing processes accordingly to maintain compliance. Our professional compliance team and lawyers will provide professional regulatory support to each client.

Documentation and Record-Keeping (Traceability system)

Maintain detailed records of the manufacturing process, including ingredient sourcing, batch formulations, quality control tests, and distribution. Keep accurate documentation to demonstrate compliance with regulatory requirements and facilitate traceability in the event of product recalls or audits.

By following these steps and adhering to strict quality control measures, Hangsen, as a leading global e-liquid manufacturer, can produce premium vape juice that meets safety standards and consumer expectations. We firmly believe in prioritizing product safety, consistency, and regulatory compliance at every stage of the production process.

About Hangsen

Hangsen is a world-leading manufacturer of e-liquid, providing premium white-label e-liquid services and customized production solutions for vape devices. Hangsen e-liquid maintains high levels of consistency, stability, safety, and regulatory compliance. Our business operations span across more than 80 countries and regions worldwide.

Feel free to Contact us at service@hangsen.com or leave a message on our Contact page.