In an era of rapid development in the e-liquid industry, traditional R&D models have struggled to meet increasingly stringent compliance standards, complex risk management requirements, and the demands of globalization operations. To embrace these industry challenges, Hangsen Technology Group, with its profound industry experience and technological prowess, has proactively implemented a digital transformation strategy, independently developing an intelligent IT management system that integrates compliance screening, product risk control, AI-driven flavor trend prediction, and production traceability. This is an industry-first groundbreaking initiative that the system redefines the R&D and production management methods within the e-liquid industry. After three years of in-depth optimization and continuous AI model training across various departments, Hangsen's self-developed IT system has now empowered over 600 partner companies.

One-Click Global Compliance Check, Facilitating Rapid Entry for Diverse Markets

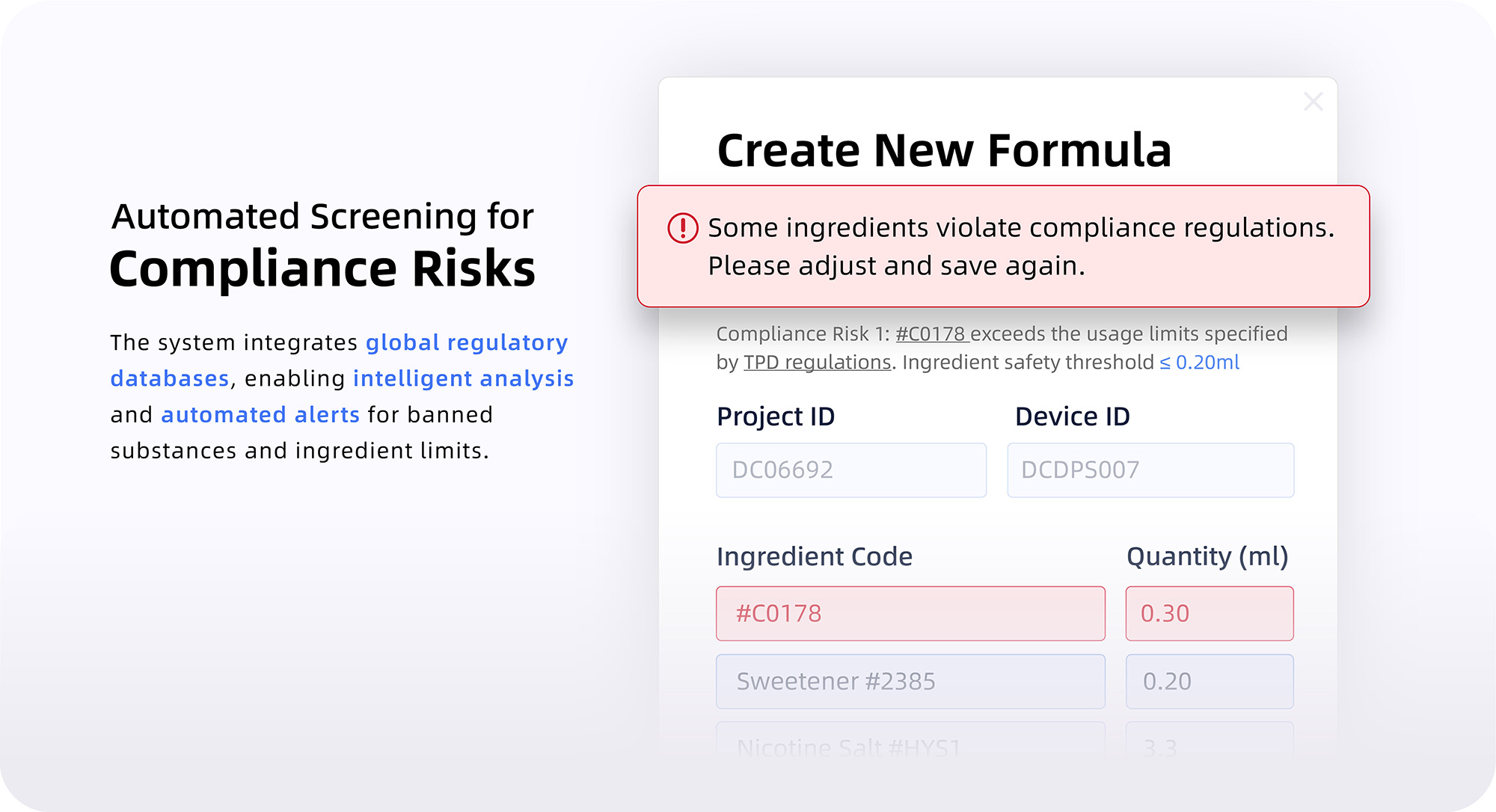

E-cigarette regulatory laws and regulations exhibit both diversity and dynamic characteristics globally, making compliance a crucial factor for many enterprises looking to enter international markets. As our customers accelerate their brand globalization strategies, managing cross-regional compliance has become increasingly complex and time-consuming.

To address this challenge, the system integrates the latest global regulatory database, enabling intelligent analysis and automatic alerting for prohibited substances and requirements, ensuring that products meet regulatory standards from the R&D stage.

This innovative approach not only preemptively mitigates compliance risks but also significantly reduces resource waste from post-development rework, optimizing the traditionally inefficient manual aspects of the R&D process. It lays a solid foundation for enterprises to rapidly expand into globally compliant markets.

2. Product Risk Control

Optimization of E-liquid and Device Compatibility

Hangsen's intelligent IT system enables preemptive risk management and automatic alerting from the project initiation stage. By utilizing advanced AI data processing algorithms and leveraging Hangsen's extensive R&D testing data, combined with years of project collaboration experience with over 300 licensed e-cigarette device manufacturers, the system accurately analyzes and alerts on risk factors in device compatibility. This helps enterprises identify and address potential issues such as burnt coils, bitter tastes, and eliquid separation etc, preventing the high costs of later optimization.

This function, after years of iterative optimization, has become a core measure for Hangsen's product risk control, significantly reducing product safety risks and customer complaints. Hangsen has provided efficient and reliable risk control support, achieving a zero-complaint record in 2024.

3. AI Flavor Trend Prediction

Data-Driven Product Innovation

Big data analysis is crucial in nowadays for all the manufacturers in different industries. Hangsen's intelligent IT management system, through a mature AI algorithm system, assists the marketing department in periodically collecting and cross-analyzing vast internal R&D data and external market information. This helps enterprises predict subtle changes in specific market flavor trends and consumer needs, enabling them to formulate forward-looking product optimization strategies.

Hangsen continually tracks global flavor preferences and R&D data trends, analyzing the composition of popular flavors to provide scientific data support for product optimization, making the innovation of targeted market formulas more statistical. From the perspective of e-liquid manufacturers, leveraging the AI intelligent analysis module to systematically integrate trends in popular product flavors, targeted market flavor trends, and internal aroma usage trends, the product R&D department can conduct more solid underlying logical reasoning. This fine-tuned e-liquid flavors to ensure each new product closely aligns with market demand.

The integration of underlying data and innovative design by the R&D team significantly enhances the brand's sensitivity to changes in the global market, allowing brand owners and manufacturers to more accurately grasp market opportunities and achieve rapid business growth.

4. Production Traceability

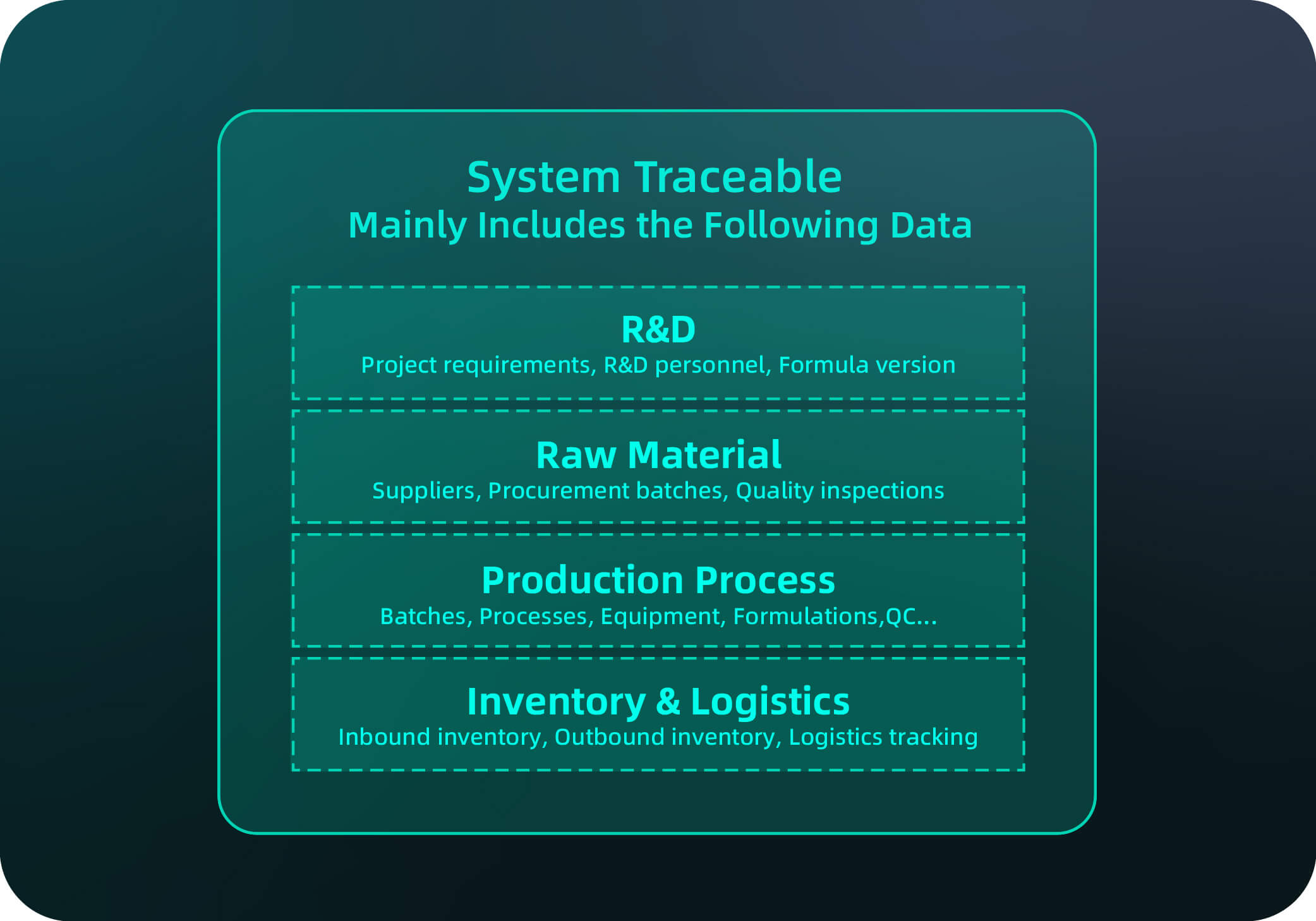

Formula Encryption, End-to-End Traceability

Today, with the increasing emphasis on e-cigarette product safety, traceability has become a core competitive advantage for high-quality e-liquid enterprises. The consistency of product flavors from formula confirmation to final delivery is highly valued in the front-end market. Hangsen's self-developed IT management system integrates complete information from R&D to delivery, including product specification, production worker, inbound and outbound logistics, and quality inspection, achieving end-to-end traceability. Additionally, the system implements multi-layered encryption processing from raw materials to finished products, effectively protecting customers’ formula data and intellectual property.

Hangsen's intelligent IT management system supports full-process digital tracking and management of project data, significantly enhancing customers' ability to track and identify product issues, effectively reducing project management risks. Within 72 hours of the golden response time, Hangsen can provide traceable documentation. Furthermore, with this comprehensive supply chain traceability system, Hangsen provides a fundamental guarantee to build brand trust, helping enterprises win more consumer recognition and support.

Transforming Enterprise Digital Management Platform, Setting New Standards in the E-liquid Industry

Hangsen's intelligent IT management system has achieved comprehensive technological innovation in compliance screening, risk control, AI-driven flavor trend prediction, and product traceability, successfully addressing many difficulties and challenges faced in traditional e-liquid R&D processes. The system not only facilitates efficient collaboration among various departments, including marketing, product development, R&D, production, and compliance, ensuring the real-time and accurate transmission of R&D data but also significantly enhances Hangsen's traceability capabilities through end-to-end online paperless and automated data circulation. Additionally, it optimizes auxiliary operations and further improves anti-error mechanisms at the production end.

This groundbreaking innovation marks a significant step forward in Hangsen's digital transformation strategy, fully demonstrating Hangsen's profound insight into future industry trends. Looking forward, Hangsen will continue to increase its investment in digital transformation, working hand in hand with customers and partners to confront the changes and challenges of the global market environment, driving the sustainable development of the e-cigarette industry. Hangsen will always walk side by side with our customers, jointly creating new chapters of innovation and progress in the e-cigarette industry.